Solution: Quality Management Automotive Industry | IATF 16949

Solution: Quality Management Automotive Industry | IATF 16949

TÜV AUSTRIA Certification IATF 16949

Certification Procedure IATF 16949

- 1.

Briefing

- 2.

Commissioning

- 3.

Pre-audit (optional)

- 4.

Level 1 certification audit

- 5.

Level 2 certification audit

- 6.

TÜV AUSTRIA certificate

- 7.

Surveillance audits

- 8.

Re-certification audit

Accreditation

Information, Target Group, Requirements

The standard IATF 16949:2016 is a globally recognized standard for quality management in the automotive industry and was published in 2016 by the International Automotive Task Force (IATF). IATF 16949 is based on the mother of all quality management standards, ISO 9001, and supplements this with some requirements for the automotive industry. A certification according to IATF 16949 is accepted worldwide by all car manufacturers and is often demanded in the supply chain in Europe and North America. The certification can only be carried out by a certification authority and corresponding auditors who have been recognized and approved by the IATF.

IATF 16949 replaces the former ISO/TS 16949:2009. Only audits according to the new automotive standard have been possible since 1 October 2017. A transitional audit allows certificates that are currently valid according to ISO/TS 16949 to be converted to IATF 16949. The transitional period comes to an end in September 2018. All certifications pursuant to ISO/TS 16949 expired on 14.09.2018.

The standard is aimed at the entire supply chain in the automotive industry, series and spare parts production, all value-adding processes in the automotive supplier industry and all manufacturers of further products demanded by customers in the automotive industry.

According to IATF, all certifying bodies are obliged to verify whether the company meets all of the requirements for a certification in accordance with the certification regulations and corresponding guidelines before performing the audit. To this end, the QM manual of each site, the plans for internal audits and a list of qualified internal auditors, operational performance trends, the QM review report of the past year, the status of customer complaints as well as a list of customers incl. a list of their requirements with respect to the QM system, has to be submitted in advance.

Advantages

- The IATF 16949 meets the internationally applicable quality safety system requirements and can already be integrated in a number of existing management systems

- The majority of car manufacturers’ demands on their suppliers can already be met by implementing this standard

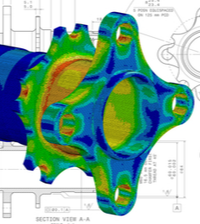

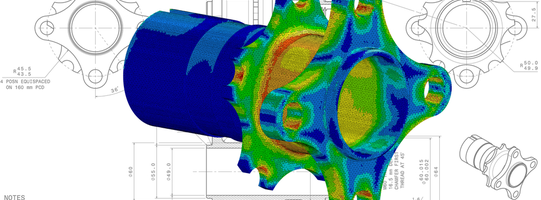

- They optimize the quality of the process and product as well as the entire value creation chain by improving efficiency. Great store is placed in the continuous improvement of the KPI and productivity during each audit (e.g. the reduction of diffusion and waste in the supply chain)

- There is a clear focus on prevention and planning in this standard, thus resulting in significant cost reductions

- Improve your reputation with customers and partners through a certification

Certification Procedure

The IATF 16949 assumes the same structure and requirements of ISO 9001:2015 but includes some additional requirements for the automotive industry.

A certification process usually takes between three and five weeks. We already take your individual needs and the urgency of the certification into account during its planning. We will determine the exact effort as well as the duration and costs together with you before the certification process. This is why every certification process begins with a briefing.

1. Briefing

We will explain the procedure to obtain your certificate in a non-binding and free meeting. Amongst those items that will be clarified in this meeting are:

- Basis requirements for your certification

- Goals and benefits of the certification

- Comparison of the business data and definition of the scope of the certification

- Discussion of your specific needs and wishes

- Determination of the next steps that are needed for the certification

You will then receive an individual offer that is tailored to your organization on the basis of this briefing.

2. Commissioning

If our offer meets with your approval, the certification body is commissioned. Once you have received confirmation of your order, the certification process begins with a joint agreement of the timetable with the responsible auditor(s).

3. Pre-audit (optional)

A pre-audit can be carried out on request. However, this is not an essential requirement for certification.

Either specific areas and/or processes or the overall situation in your organization will be audited on the basis of a jointly defined framework. Any weak spots in the documentation and implementation of the system will be identified here. A pre-audit can provide you with a status report regarding the basic suitability for certification, a detailed expertise on individual processes or the conformity with individual requirements of the respective standard on request. The audit method hereby corresponds to that of the certification audit.

4. Level 1 certification audit

The level 1 audit serves to determine whether you are suitable for certification. Location-specific conditions are assessed and any necessary information with respect to the scope is collected. The level 1 audit primarily deals with the following main points:

- Verification of the documentation for conformity and completeness compared to the requirements of the standard.

- Status of the implementation of the management system within the company: Does the existing management and the level of implementation of the management system in the organization allow a certification in principle, or are any crucial details missing?

Before the level 2 audit is performed, an audit plan for the actual certification audit will be drafted on the basis of knowledge gained of your organization and the management system and jointly agreed upon with you.

5. Level 2 certification audit

During the level 2 audit, the efficacy of the management system in place in your company will be verified. Random checks will hereby be made with respect to all of the requirements in departments and organizational units as well as along the process chain.

This audit is based on:

- The audit plan

- The respective certification standard and/or individual standard requirements specified therein

- Organization-specific documents

- General and industry-specific principles (laws, additional, industry-specific, necessary standards,..)

Following an analysis and assessment of the results, you will be informed of the outcome of the audit and any deficiencies or deviations during the final review. Corrective measures will be specified in the event of deficiencies. Subsequently, a root cause analysis and any specific documented measure will once again be verified by the audit team.

6. Issue of the certificate

The actual certification will be issued by the certification body of TÜV AUSTRIA following a successful audit and reporting on the basis of the audit report. Provided the following certification requirements have been satisfied, there is no reason why the certificate should not be issued promptly:

- Documentation and implementation of the management system

- Certification agreement (confirmation of the certification offer, the certification regulations and the T&Cs )

- Positive outcome of the audit and thus a corresponding recommendation by your audit team to the certification body

A certificate will be issued for a period of 3 years. In order to maintain the validity of the certificate over its entire term, an annual surveillance audit has to be performed with a positive outcome (12 months and 24 months after the certificate has been issued).

7. Surveillance audits

The annual surveillance audit verifies the efficacy and further development of the management system through random sampling. Surveillance audits are shorter than a normal audit and cover the deficiencies discovered in the last audit along with various key points of the requirements in the standard.

8. Re-certification audit

This has to be carried out before the certificate becomes invalid (usually after three years). In a re-certification audit (often also referred to as a repeat audit), all of the requirements are checked at random, the same as for a certification audit. The effort required for this repeat certification is less than that for an initial certification.

Following a positive decision on the certification, a new certificate valid for a further three years will be issued that also has to be confirmed by an annual surveillance audit.